Kekule’s manufacturing operations are designed to allow low-cost production of a wide variety of products in different quantities, sizes and packaging while maintaining a high level of customer service and quality. Flexible production line changeover capabilities and fast cycle times allow us to respond quickly to changes in manufacturing schedules. Our ability to design and fabricate machinery in-house for product changes and different product mixes have given us an edge over others in terms of reduced development time and costs.

Processes are developed following the US and European pharmacopeial standards. All our operations are carried out using validated systems and standard operating procedures. Synthesis route selection, process development, and validation studies are carried out in our labs with capacities ranging from milligram to kilograms. Pilot plants are equipped for engineering, quality, and commercial scale-up studies. Commercial production is carried out in our state of the art production facilities. Our QA team is involved in every step of the process to ensure that the current GMP standards are met.

Reaction Capabilites

Reaction Capabilites

- Amidation

- Grignard reaction

- Bromination

- Oxidation

- Chlorination

- Cyanations

- Nitration

- Hydrogenation

- Epoxidation

- Reduction

- Friedel-Crafts reaction

- Thioamidation

Analytical Capabilites

Analytical Capabilites

- Chromatography – HPLCs with PDA, UV and RI detector facilities, GCs with headspace, FID and TCD detectors

- Spectrophotometry – UV/Visible and FTIR, TOC

- Titrimetry – autotitrators, potentiometersTitrimetry – autotitrators, potentiometers

- Polarimetry – variable wavelength polarimeter

- Physical testing – MP, bulk testing, LOD

- Stability studies – environmental testing chambers

- Analytical micro balances

- MilliQ water system

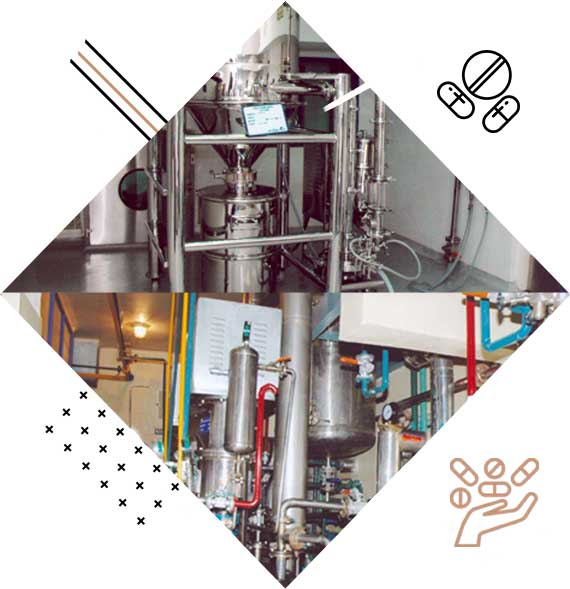

Manufacturing Facilities

Manufacturing Facilities

- Over 100 SS and Glass lined Reactors, with Capacities from 0.02 to 6KL

- Rotary vacuum dryers 0.5KL to 3KL

- Hastelloy rotary vacuum dryers

- High vacuum distillation setup of various capacities

- SS tray dryers

- Dry HCl gas passing system and Hydrogenation system

- Temp range: -20 to +270C

- Pressure Range: upto 35Kg/cm2

- Vacuum: 0.5mm of Hg

Quality Focus

Quality Focus

Because quality is critical…

We are continuing to promote quality throughput for our operations, from procuring raw materials to distributing the finished product. At Kekule, high quality raw materials ensures that quality starts before the product is made. We continue to execute our quality and compliance improvement plans. The quality processes in place today provide a solid foundation for a strong pharmaceutical culture we are building upon.